Imikhiqizo

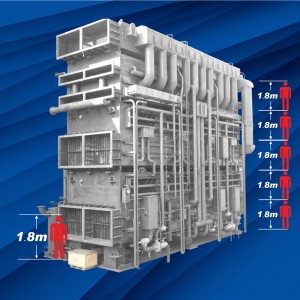

Iphampu Yokushisa Yekilasi II

Isimiso Sokusebenza

Ngokuvamile, iphampu yokushisa ye-Class II iwuhlobo olulodwa lwedivayisi ye-LT eqhutshwa ukushisa imfucuza, emunca ukushisa emanzini ashisayo angcolile ukuze ikhiqize amanzi ashisayo ngezinga lokushisa eliphakeme kunamanzi ashisayo asakazwa yimfucuza.Isici esijwayelekile kakhulu salolu hlobo lwephampu yokushisa ukuthi ingakwazi ukukhiqiza amanzi ashisayo ngezinga lokushisa eliphakeme kunamanzi ashisayo achithayo ngaphandle kweminye imithombo yokushisa.Kulesi simo, ukumosha amanzi ashisayo nakho kuwumthombo wokushisa.Kungakho iphampu yokushisa yokumunca Yekilasi II yaziwa njengephampu yokushisa ekhulisa izinga lokushisa.

Amanzi ashisayo angcolile angena ku-generator kanye ne-evaporator ngochungechunge noma ngendlela efanayo.Amanzi ayisiqandisi amunca ukushisa emanzini angcolile ashisayo ku-evaporator, abese ehwamuka abe umhwamuko oyisiqandisi futhi angene ku-absorber.Isixazululo esigxilile ku-absorber siba isisombululo esihlanjululwe futhi sikhulula ukushisa ngemva kokumunca umhwamuko oyisiqandisi.Ukushisa okumuncwe kushisa amanzi ashisayo ezingeni lokushisa elidingekayo.

Ngakolunye uhlangothi, isixazululo esihlanjululwe singena ku-generator ngemva kokushintshana kokushisa nesisombululo esigxilile nge-heater bese sibuyela ku-generator, lapho sishiswa ngamanzi ashisayo angcolile futhi sigxilwe kusisombululo esigxilile, bese sihanjiswa ku-absorber.Umhwamuko wesiqandisi okhiqizwe kujeneretha unjalo

ilethwa ku-condenser, lapho ifinyezwa emanzini ngamanzi okupholisa okushisa aphansi futhi ilethwe

ku-evaporator ngepompo yesiqandisi.

Ukuphinda lo mjikelezo kuhlanganisa inqubo yokushisa eqhubekayo.

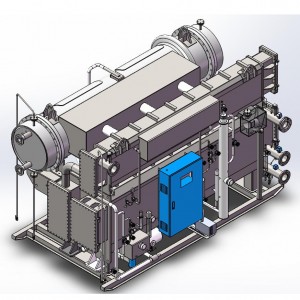

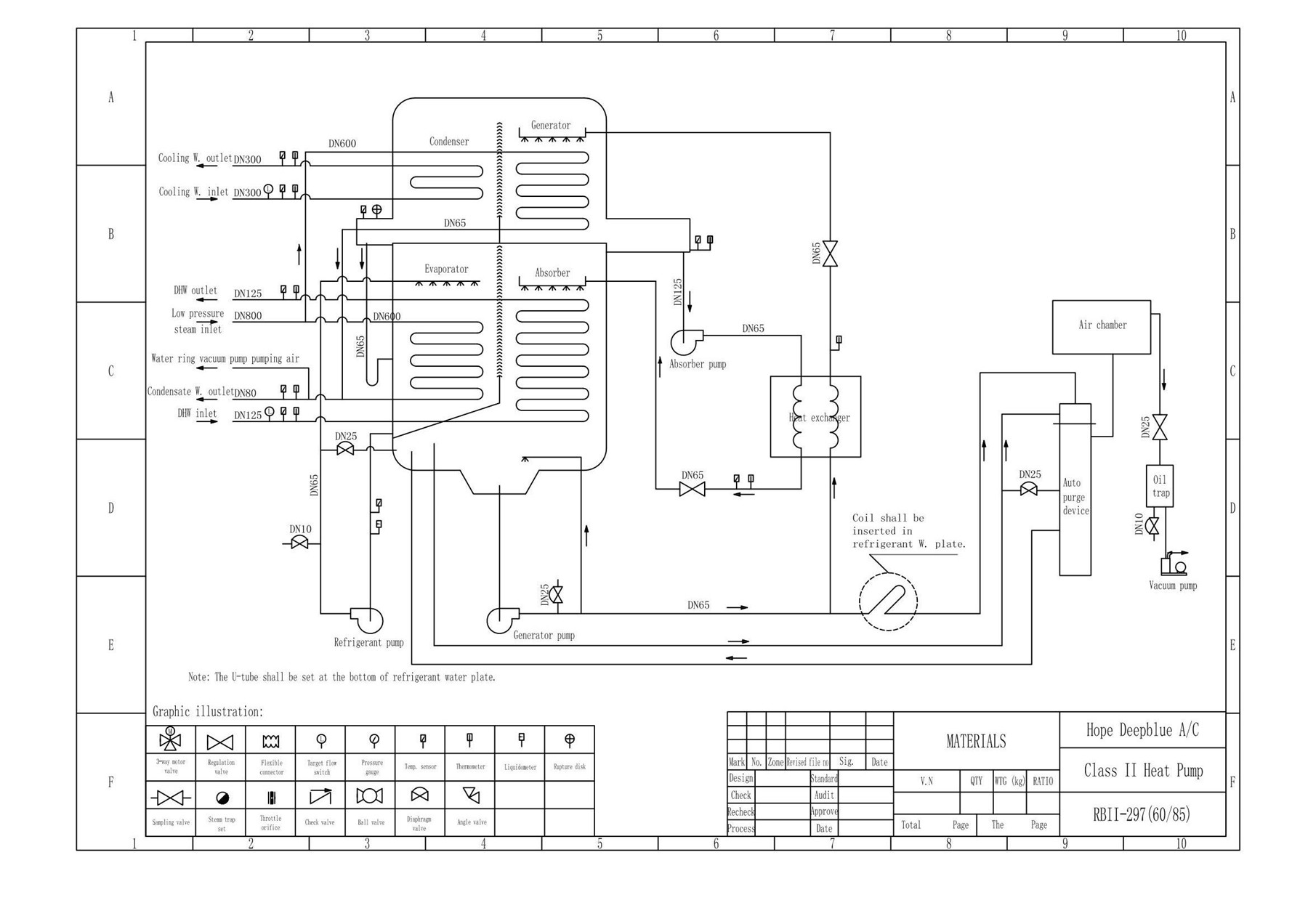

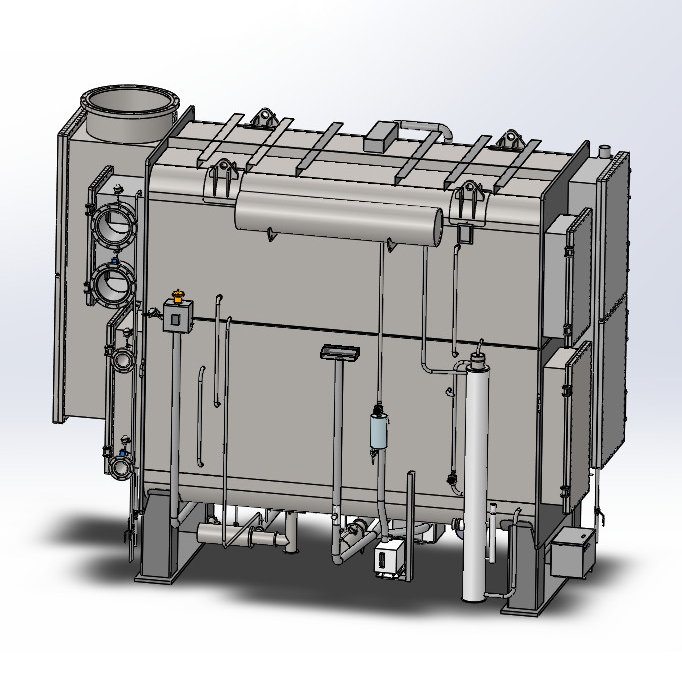

Umdwebo Wokugeleza Kwenqubo

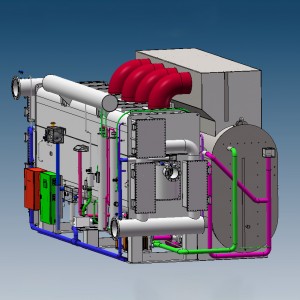

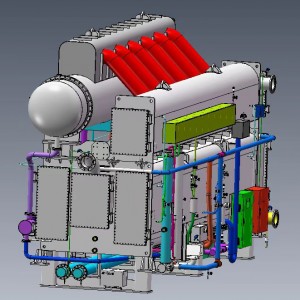

Izingxenye Eziyinhloko kanye Nemisebenzi

1.Ijeneretha

Umsebenzi Wesizukulwane: Ijeneretha ingumthombo wamandla wepompo yokushisa.Umthombo wokushisa oqhutshwayo ungena kujeneretha bese ushisisa isisombululo se-LiBr esihlanjululwe.Amanzi esixazululweni esihlanjululwe ayahwamuka ngesimo se-steam esiqandisini futhi angena ku-condenser.Phakathi naleso sikhathi, isixazululo esihlanjululwe sigxila kwisisombululo esigxilile.

Ihambisana nesakhiwo segobolondo neshubhu, ijeneretha ihlanganisa ishubhu lokudlulisa ukushisa, ishidi leshubhu, ipuleti lokusekela, igobolondo, ibhokisi lesitimu, igumbi lamanzi nepuleti le-baffle.Njengomkhumbi wokucindezela okuphezulu kakhulu ngaphakathi kwesistimu yephampu yokushisa, ijeneretha inevacuum yangaphakathi ecishe ibe uziro (i-micro negative-pressure).

2. I-Condenser

Umsebenzi we-Condenser: I-condenser iyunithi yokukhiqiza ukushisa.isitimu esiqandisini esivela kujeneretha singena ku-condenser futhi sishise i-DHW ezingeni lokushisa eliphakeme.Khona-ke umphumela wokushisa ufinyelelwa.Ngemva kokuba isitimu esiqandisini sishise i-DHW, siyajiya sibe sesiqandisi bese singena ku-evaporator.

Ihambisana nesakhiwo segobolondo neshubhu, i-condenser ihlanganisa ishubhu lokudlulisa ukushisa, ishidi leshubhu, ipuleti lokusekela, igobolondo, ithangi lokugcina amanzi negumbi lamanzi.Ngokuvamile, i-condenser ne-generator ixhunywe ngokuqondile ngamapayipi, ngakho-ke inokucindezela okufanayo.

3. I-Evaporator

Umsebenzi we-Evaporator: I-evaporator iyunithi yokubuyisela ukushisa okulahliwe.Amanzi ayisiqandisi asuka ku-condenser ayahwamuka ebusweni beshubhu yokudlulisa ukushisa, asuse ukushisa futhi apholise i-CHW ngaphakathi kweshubhu.Ngaleyo ndlela ukushisa kwemfucuza kuyabuyiselwa.umusi oyisiqandisi ohwamukayo ebusweni beshubhu yokudlulisa ukushisa ungena ku-absorber.

Ihambisana nesakhiwo segobolondo neshubhu, i-evaporator ihlanganisa ishubhu lokudlulisa ukushisa, ishidi leshubhu, ipuleti lokusekela, igobolondo, ipuleti le-baffle, i-drip tray, isifafazi negumbi lamanzi.Ingcindezi yokusebenza ye-evaporator icishe ibe ngu-1/10 wengcindezi ye-generator.

4. Umuthi

Umsebenzi we-Absorber: I-absorber iyiyunithi yokukhiqiza ukushisa.Umusi oyisiqandisi ovela ku-evaporator ungena ku-absorber, lapho uthathwa khona yisisombululo esigxilile.Isixazululo esigxilile siphenduka isisombululo esihlanjululwe, esihanjiswa ngepompo emjikelezweni olandelayo.Nakuba isitimu esiqandisini simunca isixazululo esigxilile, kukhiqizwa ukushisa okukhulu okumuncwa futhi kushisise i-DHW ezingeni lokushisa eliphakeme.Ngakho umphumela wokushisa ufinyelelwa.

Ihambisana nesakhiwo segobolondo neshubhu, isibambisi sihlanganisa ishubhu yokudlulisa ukushisa, ishidi leshubhu, ipuleti lokusekela, igobolondo, ipayipi lokuhlanza, isifafazi negumbi lamanzi.I-absorber iwumkhumbi wokucindezela okuphansi kakhulu ngaphakathi kwesistimu yepompo yokushisa futhi ingaphansi komthelela omkhulu kakhulu ovela emoyeni ongaconsi.

5. I-Heat Exchanger

Umsebenzi Wokushintshanisa Ukushisa: Isishintshi sokushisa iyunithi yokutakula ukushisa esetshenziselwa ukubuyisela ukushisa kusixazululo se-LiBr.Ukushisa esixazululweni esigxilile kudluliselwa isishintshi sokushisa kusixazululo esihlanjululwe sokuthuthukisa ukusebenza kahle kokushisa.

Ihlanganisa nesakhiwo sepuleti, isishintshi sokushisa sinokusebenza kahle okuphezulu kokushisa kanye nomthelela ophawulekayo wokonga amandla.

6. Isistimu Yokuhlanza Umoya Okuzenzakalelayo

Umsebenzi Wesistimu: Isistimu yokuhlanza umoya isilungele ukumpompa umoya ongafinyeleli empompini yokushisa futhi igcine isimo se-vacuum ephezulu.Ngesikhathi sokusebenza, isixazululo esihlanjululwe sigeleza ngenani eliphezulu ukuze sikhiqize indawo yokucindezela ephansi yasendaweni ezungeze i-ejector nozzle.Ngakho-ke umoya ongacondensable ukhishwa empompini yokushisa.Isistimu isebenza kanyekanye nephampu yokushisa.Ngenkathi iphampu yokushisa isebenza, isistimu ezenzakalelayo isiza ukugcina i-vacuum ephezulu ngaphakathi nokuqinisekisa ukusebenza kwesistimu nempilo yesevisi eyengeziwe.

Uhlelo lokuhlanza umoya luwuhlelo olwakhiwe i-ejector, i-cooler, isicupho samafutha, isilinda somoya kanye ne-valve.

7. Iphampu Yesixazululo

Iphampu yesixazululo isetshenziselwa ukuletha isisombululo se-LiBr futhi ivikele ukugeleza okujwayelekile kwezisetshenziswa ezisebenzayo eziwuketshezi ngaphakathi kwepompo yokushisa.

Iphampu yesixazululo iyiphampu ephakathi nendawo evalelwe ngokuphelele, ekheniwe enokuvuza koketshezi oluyiziro, umsindo ophansi, ukusebenza okuphezulu okuvikela ukuqhuma, ukulungiswa okuncane kanye nempilo ende yesevisi.

8. Iphampu Yesiqandisi

Iphampu yesiqandisi isetshenziselwa ukuletha amanzi ayisiqandisi kanye nokuqinisekisa isifutho esivamile samanzi ayisiqandisi ku-evaporator.

Iphampu yesiqandisi iyiphampu ephakathi nendawo evalelwe ngokuphelele, ekheniwe enokuvuza koketshezi oluyiziro, umsindo ophansi, ukusebenza okuphezulu okuvikela ukuqhuma, ukunakekelwa okuncane kanye nempilo ende yesevisi.

9. Iphampu yeVacuum

Iphampu yevacuum isetshenziselwa ukuhlanza i-vacuum esigabeni sokuqala kanye nokuhlanzwa komoya esigabeni sokusebenza.

Iphampu ye-vacuum inesondo elijikelezayo.Inkinobho ekusebenzeni kwayo ukuphatha uwoyela we-vacuum.Ukuvinjelwa kwe-emulsification kawoyela kunomthelela omuhle ngokusobala ekusebenzeni kokuhlanzwa komoya futhi kusiza ukwandisa impilo yesevisi.

10. IKhabhinethi kagesi

Njengesikhungo sokulawula sepompo yokushisa yokumuncwa kwesigaba II, ikhabethe likagesi ligcina izilawuli eziyinhloko nezingxenye zikagesi.

Ukubuyisela Ukushisa Kwemfucuza.Ukongiwa kwamandla kanye nokuncishiswa kokukhipha

Ingasetshenziselwa ukubuyisela amanzi ashisayo angcolile e-LT noma umusi we-LP ekuphehleni amandla ashisayo, ukubhola uwoyela, insimu ye-petrochemical, ubunjiniyela bensimbi, inkambu yokucubungula amakhemikhali, njll. Ingasebenzisa amanzi omfula, amanzi angaphansi komhlaba noma omunye umthombo wamanzi emvelo, iguqule amanzi ashisayo e-LT. emanzini ashisayo e-HT ngenjongo yokushisisa isifunda noma ukushisisa inqubo.

Uhlobo Lwekilasi II olunezinga lokushisa eliphakeme lamanzi ashisayo

Iphampu yokushisa ye-Class II ingathuthukisa izinga lokushisa lamanzi ashisayo angcolile libe ngu-100°C ngaphandle komunye umthombo wokushisa.

Umthelela okabili (Usetshenziselwa Ukupholisa/Ukushisa)

Iqhutshwa igesi yemvelo noma isitimu, iphampu yokushisa yokumuncwa okukabili ingabuyisa ukushisa kukadoti ngokusebenza kahle okuphezulu kakhulu (i-COP ingafinyelela ku-2.4).Ifakwe kokubili umsebenzi wokushisisa nokupholisa, ikakhulukazi osebenza esidingweni sokushisisa/ukupholisa ngesikhathi esisodwa.

Ukumuncwa kwezigaba ezimbili kanye nezinga lokushisa eliphakeme

Iphampu yokushisa yesigaba II yesigaba sesibili ingathuthukisa izinga lokushisa lamanzi ashisayo amoshekayo libe ngu-80°C ngaphandle komunye umthombo wokushisa.

• Imisebenzi yokulawula okuzenzakalelayo ngokugcwele

Isistimu yokulawula (AI, V5.0) ifakwe imisebenzi enamandla nephelele, efana nokhiye owodwa wokuqala/ukuvala, isikhathi sokuvula/ukuvala, isistimu yokuvikela ekhulile, ukulungisa okuzenzakalelayo okuningi, ukuxhuma kwesistimu, isistimu yochwepheshe, umshini womuntu. inkhulumomphendvulwano(izilimi eziningi), ukwakha izixhumanisi ezizenzakalelayo, njll.

• Qedela umsebenzi wokuzihlola nokungajwayelekile kweyunithi kanye nomsebenzi wokuvikela

Isistimu yokulawula (AI, V5.0) ihlanganisa 34 ukungavamile kokuzihlola kanye nemisebenzi yokuvikela.Izinyathelo ezizenzakalelayo zizothathwa yisistimu ngokwezinga lokungajwayelekile.Lokhu kuhloswe ngakho ukuvimbela izingozi, ukunciphisa ukusetshenzwa kwabantu kanye nokuqinisekisa ukusebenza okuqhubekayo, okuphephile futhi okuzinzile kokubandayo.

• Umsebenzi wokulungisa umthwalo oyingqayizivele

Isistimu yokulawula (AI, V5.0) inomsebenzi wokulungisa umthwalo oyingqayizivele, ovumela ukulungiswa okuzenzakalelayo kokuphuma kwe-chiller ngokuya ngomthwalo wangempela.Lo msebenzi awusizi nje kuphela ukunciphisa isikhathi sokuqalisa/ukuvalwa nesikhathi sokuhlanjululwa, kodwa futhi ufaka isandla ekusebenzeni okungenzi lutho nokusetshenziswa kwamandla.

• Ubuchwepheshe obuhlukile bokulawula ivolumu yokujikeleza kwesixazululo

Isistimu yokulawula (AI, V5.0) isebenzisa ubuchwepheshe obusha bokulawula be-ternary ukulungisa umthamo wokujikeleza kwesisombululo.Ngokwesiko, imingcele kuphela yezinga le-liquid ye-generator isetshenziselwa ukulawula umthamo wokujikeleza kwesisombululo.Lobu buchwepheshe obusha buhlanganisa ukufaneleka kokugxilisa ingqondo&izinga lokushisa lesixazululo esigxilile kanye nezinga loketshezi kujeneretha.Ngaleso sikhathi, ubuchwepheshe bokulawula obuguquguqukayo obuthuthukisiwe busetshenziswa kuphampu yesixazululo ukuze iyunithi ikwazi ukufeza umthamo wesixazululo osakazwa kahle.Lobu buchwepheshe buthuthukisa ukusebenza kahle futhi bunciphisa isikhathi sokuqalisa nokusetshenziswa kwamandla.

• Ubuchwepheshe bokulawula ukuhlushwa kwesixazululo

Uhlelo lokulawula (AI, V5.0) lusebenzisa ubuchwepheshe obuyingqayizivele bokulawula ukugxilisa ingqondo ukuze kunikwe amandla ukuqapha/ukulawula kwesikhathi sangempela sokugxilisa ingqondo nomthamo wesisombululo esigxilile kanye nevolumu yamanzi ashisayo.Le sistimu ingagcina ipholile ngaphansi kokuphephile futhi izinzile esimweni sokugxila okuphezulu, ithuthukise ukusebenza kahle kwe-chiller futhi ivikele ukucwebezela.

• Umsebenzi wokuhlanza umoya ozenzakalelayo ohlakaniphile

Isistimu yokulawula (AI, V5.0) ingakwazi ukubona ukuqapha kwesikhathi sangempela kwesimo se-vacuum futhi ikhiphe ngokuzenzakalelayo umoya ongaconsi.

• Ukulawula okuhlukile kokumisa ukuhlanjululwa kwe-dilution

Lolu hlelo lokulawula (i-AI, i-V5.0) lungalawula isikhathi sokusebenza samaphampu ahlukene adingekayo ekusebenzeni kwe-dilution ngokusho kokugxila kwesisombululo, izinga lokushisa elizungezile kanye nomthamo wamanzi ayisiqandisi asele.Ngakho-ke, ukugxilisa ingqondo okuphelele kungagcinwa ku-chiller ngemva kokuvalwa.I-Crystallization ivinjelwe futhi isikhathi sokuqalisa kabusha kwe-chiller siyafinyezwa.

• Uhlelo lokuphatha ipharamitha esebenzayo

Ngokusebenzelana kwalolu hlelo lokulawula (AI, V5.0), u-opharetha angenza noma yimiphi imisebenzi elandelayo kumapharamitha abalulekile angu-12 ahlobene nokusebenza okupholile: isibonisi sesikhathi sangempela, ukulungisa, ukulungiselelwa.Amarekhodi angagcinelwa imicimbi yokusebenza yomlando.

• Uhlelo lokulawula amaphutha eyunithi

Uma noma yisiphi isixwayiso sephutha ngezikhathi ezithile siboniswa kusixhumi esibonakalayo sokusebenza, le sistimu yokulawula (AI, V5.0) ingathola futhi inemininingwane yephutha, iphakamise isisombululo noma isiqondiso sokuxazulula inkinga.Ukuhlelwa nokuhlaziywa kwezibalo zamaphutha omlando kungenziwa ukuze kube lula isevisi yokulungisa ehlinzekwa abaqhubi.